- Gate valve

-

- DN1000 Extension stem double flange soft seal gate valveDIN F4 resilient seated gate valveDN450-1200 Resilient Seated Gate ValveDIN F5 resilient seated gate valveSocket connection soft seal gate valveUnderground cap soft seal gate valveBS5163 rising stem soft seal gate valveHard seal gate valveAPI slab Gate ValveStainless steel flange gate valveWafer knife gate valvePneumatic gate valveSoft seal gate valveExtension stem gate valveUL/FM fire protection groove ends gate valveRising stem forged steel gate valvecarbon steel gate valveStainless steel threaded gate valveDIN soft seal gate valveANSI soft sealing gate valve 200PSICast iron gate valveBS resilient seated gate valve

- Butterfly valve

-

- DN900 pneumatic triple eccentric hard seal butterfly valveD643H Triple Eccentric Butterfly ValveD343H Hard seal butterfly valveMulti standard EPDM seated butterfly valveSingle flange butterfly valveDN2000 Double eccentric butterfly valveFlange butterfly valveLug butterfly valveWafer butterfly valve with handleWorm gear operated butterfly valveWafer lined fluorine butterfly valveStainless steel wafer butterfly valveStainless steel flanged butterfly valveThree eccentric flange butterfly valvePneumatic flanged butterfly valvePneumatic wafer butterfly valveTriple eccentric butterfly valve wafer typeWafer butterfly valve ULC approvedInflatable seat butterfly valveHigh performance butterfly valveGrooved end butterfly valveElectric soft seal butterfly valveFlange fluorine lined butterfly valveHandle aluminum butterfly valveWorm Gear Aluminum Butterfly ValveFull PTFE lined butterfly valve wafer typeOne stem no-pin wafer butterfly valveMulti standard aluminum stem butterfly valveStainless Steel wafer Butterfly ValveAluminium handle operated lug butterfly valveLever Operated Flange Butterfly ValveButterfly valve stemButterfly valve discButterfly valve seat

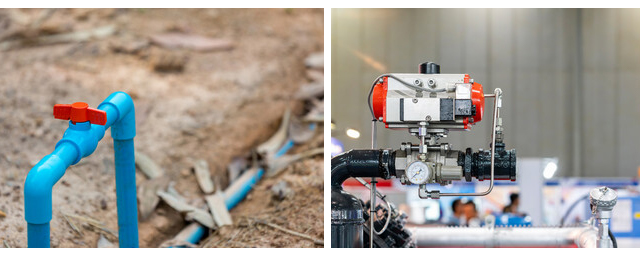

- Ball valve

-

- DN1400 top-mounted eccentric semi-ball valveFlanged three-way ball valveFully welded ball valveNatural gas ball valveHigh platform flange ball valve1 PC ball valveFixed ball valvePTFE seat flanged ball valveMetal seat ball valveAPI 6D ball valve3 Piece ball valveFull Bore 3 way ball valve L-Port3 Way T-Port ball valve2PC Ball valve female thread stainless steel

- Globe Valve

-

- API Carbon Steel Globe ValveBellows Globe ValveStainless steel flange globe valveStainless steel thread S type globe valveStainless steel thread B type globe valveCast Steel Globe ValvePiston Globe ValveWCB Carbon Steel Globe Check Valveelectric motorized control stainless steel SS316 globe valveBrass Globe ValveCryogenic Globe valveHT200 Globe ValveThreaded Stainless Steel Globe ValveGG25 Globe ValveANSI API Cast Steel And Stainless Steel Globe valve

- Check valve

-

- Rubber seal check valveDN800 Slow closing check valveDN800 Rubber Disc Check ValveButterfly Buffering Check Valvecheck valve with counter weightSilent Check ValveWCB Swing check valveSwing Check ValveSingle Chip Check Valve H74WStainless Steel Wafer Check ValveSwing Start Check ValveFoot check valveAPI Swing Check ValveDIN Flange check valveSingle plate check valveLifting Check ValveBottom ValveHammer Diminish Noises Check ValveWafer Check ValveWafer dual plate check valve

- Control valve

-

- Static Balancing ValveCage Guided Sleeve Globe Control ValveDN1000 Piston Flow Regulating ValveDN1600 Electric Actuator Flow Regulating ValvePneumatic Flanged Butterfly ValvePneumatic Wafer Butterfly ValveAngle Seat ValvePneumatic gate valveElectric three-way control valveElectric sleeve control valve

- Water Meter

-

- Vertical Type Water MetersStainless steel threaded water meterPiston water meterPlastic water meterMore flow rotor dry water meterspiral vane flange water meterCI wotlman water meter with pulse outputLXCLG(R) Vertical removable element woltman cold (hot) water meterSingle flow rotor dry water meterPrepaid Token Water MeterElectromagnetic flowmeterRotary Piston Liquid Sealed Water MeterRotary Piston Liquid Sealed Water Meter

- Air valve

-

- Double ball exhaust valveDoubleair Air Valve SaudiDoubleair Air Valve Southeast AsiaDoubleair Air Valve South AmericaDouble Air ValveThreaded Air ValveSingle Air ValveTriple Functions Air ValveAutomatic Air Release ValveAutomatic release valveAutomatic exhaust valveComposite Exhaust Air ValveBrass exhaust valveDouble Ball Air Valve

- Pipe Repair & Coupling

-

- Flexible Multi-Function Pipe Coupling ZFJ-SSS Semi-Circle Pipe Repair Clamp SJW-HDuctile Iron Band Repair ClampStainless Steel Band Repair ClampDouble-Section Pipe Repair CouplingFolding Type Pipe RepairSingle-Section Multi-Function Pipe Coupling MF-SGear-Ring Type Multi-Function Pipe Coupling GR-SZBW Damping Corrugated Hose

- Dismantling Joint

-

- VSSJAFC(CC2F) Detachable Flange Transmission JointVSSJA-2(B2F) Double Flange Limited Expansion JointVSSJA-1(BF) Single Flange Limited Expansion JointVSSJA(AF) Flange Loose Expansion JointJGD-B Threaded Rubber JointZBW Damping Corrugated HoseKXT-S Flexible Dual-Spherical Rubber JointKXT Rubber Soft JointFlange Adaptor

What are the applicable occasions for ball valves?

The function of the ball valve on the pipeline is mainly used to cut off, distribute and change the flow direction of the medium. The ball valve designed with a V-shaped opening also has a good flow regulation function.

The ball valve not only has a simple structure and good sealing performance, but also has a small size, light weight, low material consumption, small installation size within a certain nominal throughput range, small driving torque, easy operation, and easy to realize rapid opening and closing. It is the most popular ball valve in recent years. One of the fastest growing valve varieties in the past decade.

The ball valve only needs to be rotated 90 degrees and a small rotational torque to close tightly. In the completely equal valve body, the cavity provides a straight flow path with small resistance for the medium. It is generally considered that the ball valve is most suitable for direct opening and closing, but recent developments have designed the ball valve to have the function of throttling and controlling flow.

The main feature of the ball valve is that it has a compact structure and is easy to operate and maintain. It is suitable for general working media such as water, solvents, acids and natural gas, and is also suitable for media with harsh working conditions, such as oxygen, hydrogen peroxide, methane and ethylene. The ball valve body can be integral or combined.

With the technological advancement of ball valves, they will be more widely used in the foreseeable short term, especially in oil and gas pipelines, refinery cracking units and the nuclear industry. In addition, ball valves will also become one of the leading valve types in large and medium diameter, medium and low pressure fields in other industries.

The main advantages of ball valves:

① The fluid resistance is small, and its resistance coefficient is equal to that of a pipe section of the same length;

②Simple structure, small size and light weight;

③Tight and reliable. At present, plastic is widely used as the sealing surface material of ball valves, which has good sealing performance and has also been widely used in vacuum systems;

④ Easy to operate, quick to open and close, just rotate 90° from fully open to fully closed, convenient for long-distance control;

⑤Easy to maintain, the ball valve has a simple structure, the sealing ring is generally movable, and it is easy to disassemble and replace;

⑥When fully open or fully closed, the sealing surfaces of the ball and valve seat are isolated from the medium. When the medium passes, it will not cause erosion of the valve sealing surface;

⑦Wide range of application, the diameter ranges from a few millimeters to several meters, and can be applied from high vacuum to high pressure.

Applicable occasions of ball valve:

①Chemical industry

In the chemical industry, ball valves are widely used in various chemical reactors, storage tanks, pipelines and other equipment. Because ball valves have excellent corrosion resistance and sealing performance, they can effectively control the flow and sealing of chemical substances and prevent media leakage and contamination.

②Oil and natural gas industry

In the oil and gas industry, ball valves are widely used in oil and gas fields, oil pipelines, liquefied gas stations and other places. Because ball valves are resistant to high pressure, wear, and corrosion, they can effectively control the flow and sealing of oil and gas to ensure normal production and transportation of oil and gas fields.

③Water conservancy project

In water conservancy projects, ball valves are widely used in dams, reservoirs, hydropower stations and other places. Because ball valves have the characteristics of simple structure, easy operation, and high reliability, they can effectively control the flow and sealing of water to ensure the safety and normal operation of water conservancy projects.

④Agricultural irrigation

In agricultural irrigation, ball valves are widely used in ditches, water pumps, irrigation systems and other places. Because ball valves have the characteristics of simple structure, easy operation, and affordable price, they can effectively control the flow and sealing of water and ensure the normal operation of agricultural irrigation.

⑤Urban water supply and drainage

In urban water supply and drainage, ball valves are widely used in water plants, sewage treatment plants, sewers and other places. Because ball valves are corrosion-resistant, wear-resistant, and have long service life, they can effectively control the flow and sealing of water and ensure the normal operation of urban water supply and drainage.

Ball valve application principles:

For main oil and natural gas transmission lines that need to be cleaned and buried underground, ball valves with full through-pass and fully welded structures should be used;

For those buried on the ground, choose full-pass welded or flange-connected ball valves; for branch pipes, choose flange-connected, welded, full-pass or reduced-diameter ball valves.

For product oil transportation pipelines and storage equipment, flange-connected ball valves are used.

On city gas and natural gas pipelines, floating ball valves with flange connection and internal thread connection are used.

In the oxygen pipeline system in the metallurgical system, fixed ball valves with flange connections should be selected that have undergone strict degreasing treatment.

For piping systems and devices with low-temperature media, low-temperature ball valves with valve covers should be used.

For the piping system of the catalytic cracking unit of the oil refining unit, a lift-rod ball valve can be used.

For devices and piping systems with corrosive media such as acids and alkalis in chemical systems, it is appropriate to use all-stainless steel ball valves made of austenitic stainless steel and with polytetrafluoroethylene as the valve seat seal.

Metal-to-metal sealing ball valves can be used for pipeline systems or devices with high-temperature media in metallurgical systems, power systems, petrochemical installations, and urban heating systems.

When flow adjustment is required, a worm gear-driven, pneumatic or electric regulating ball valve with a V-shaped opening can be used.